measured by:

What makes the Kellner-acoustic housing so unique?

Stable, self-supporting sound-insulating housing

Effective & smart construction

Optimized sound damping

Simplest installation & maintenance

Extremely large-scale louvres plus an additional separation of the air flow ducts at the discharge louvers to prevent incorrect air flows at partial load operation of outdoor units with 2 fans. The revised lock system of the flexible air-separator hose ensures complete separation of the intake and exhaust air - even at the highest fan speed.

A multi-layered, asymmetrical design of the louvre-packs with double sound adsorption and many detail improvements in the housing, resulting in a perfectly adapted sound insulation for all kind of air conditioners and heat pumps of up to -21 dB(A)*2, *3, *4

The factory-assembled complete solution offers the greatest possible accessibility for installation and service thanks to large front doors and new louvre-packs with snap fasteners, which can be pivoted in seconds and reduces installation and maintenance costs.

Extremely stable base frame

Flexible build-in

100% weather proof

The self-supporting base frame made of massive steel profiles, cross struts and integrated drain pan can be used with the height-adjustable feet on any paved surface - even without substructure. The housing is 100% non-tilting even with highest wind loads in exposed locations.

Thanks to the easy movable and stable crossbeam-system, a fast and flexible adaptation for the insertion of all air conditioners and heat pumps without drilling is realized. Standard built-in damping pads made of Sylomer avoid any transmission of structure-borne noise to the ground.

The brand new damping material is totally weatherproof and water resistant. It is inserted and screwed instead of glued. This maintains the shape of the louvres and particularly the functionality of the built-in air conditioning units over years without any problems during operation.

Best efficiency

Innovative „split-bottom“*5

Environmental friendly materials

Newly designed sound insulation louvre-packs with barely measurable pressure drop (<15 Pa)*1 are the key to the best efficiency of the built-in air-conditioning units. The fans are running on low fan speed because of less counter pressure which results in a lower dynamic sound level in real working conditions.

1: Data measured by TÜV Austria (Technical Supervisory Association)

2: Depending on unit manufacturer and model

3: Data measured according to DIN EN ISO 6914-2

4: Version with deflector plates and Ultra-louvres

5: Utility model protection for components and functions under AT15899-U2-2018 and GM 50161/2018

2: Depending on unit manufacturer and model

3: Data measured according to DIN EN ISO 6914-2

4: Version with deflector plates and Ultra-louvres

5: Utility model protection for components and functions under AT15899-U2-2018 and GM 50161/2018

The housing is equipped as standard with an insulated, closed drain pan as a patented split-bottom *5 and reliably directs rainwater and condensation water out of the housing via slit-shaped gutters into a drain gutters (accessory). This keeps the surface underneath the housing dry and ice-free in winter time.

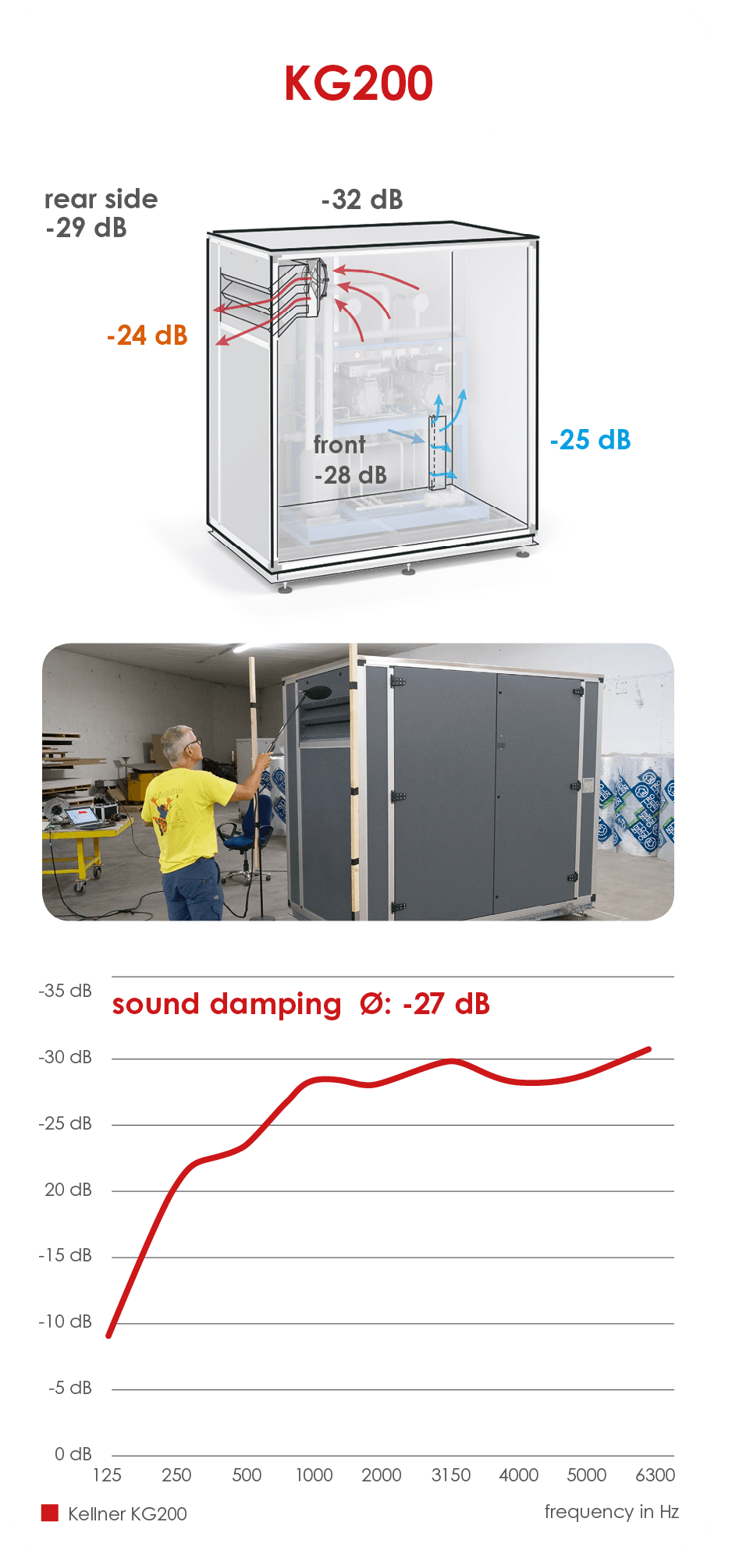

Soundproofing for the highest demands

and satisfied residents

Realistic damping values for high planning security

Ever-increasing requirements of municipalities, stricter noise regulations and sensitive neighbors make constructive and material-technical high-quality sound insulation necessary to fulfill the specifications and to maintain the device function over many years. Therefore the Kellner-acoustic housings are constantly being further developed and measured in very precise sound tests by means of envelope detection methods.

These very realistic and traceable measurements are executedby an independent, external civil engineer in accordance with applicable standards ÖNORM EN ISO 9614-2, ÖNORM EN ISO11546-1 and ÖNORM EN ISO 717-1. The tests are carried out under laboratory conditions with a ball loudspeaker as a constant and homogeneously radiating sound source, externally by means of a sound intensity probe meandered.

In these exact measurements, the characteristic of the sound attenuation in all propagation directions is recorded. In this way exact precalculations of the expected noiseemission for sensitive acoustic projects can be created.

This allows the design office, an acoustician and the authority, to obtain a very realistic estimate of the expected sound levels. This results in a high degree of planning security, also for the operator, end customers and for residents.

Top damping + lowest static pressure drop = highest efficiency!

The Kellner-acoustic housing perfectly combines both!

This makes the difference: Lowest static pressure drop!

The structural design and the functionality of the Kellner-acoustic housing are defined by the special shape and arrangement of the „lamella-packs“ (louvres/silencers). Depending on the type of housing and the design-related characteristics of the installed air conditioners or heat pumps, these louvres are shaped and dimensioned differently.

These louvres differ significantly in material structure andin the form of conventional louvres, which are used incommercially available silencers.

The fan characteristics of the horizontally blowing fans ofsplit air conditioners and heat pumps show a very low availablepressure and are therefore suitable in principle for afree blow-out. Fans of vertical blowing VRF air conditionershave a slightly higher pressure, which, however, only occurs

at the highest fan speeds.

Therefore, a specially constructed, special pressure test channel for measuring the pressure losses of different louvrepacks was built. Depending on the direction of flow and the suction or pressure air-flow (discharge side), the characteristics of the louvres can be precisely adapted to the behavior and optimized with a speed-controlled fan with a similar fancharacteristic as it is built-in the air conditioning units.

In addition to the special shape of the different louvre-packs, the free cross section and subsequently the lowest possible air-flow velocity are decisive for a low pressure loss and thus for an efficient and trouble-free operation of the installed outdoor units.

cross sections with the highest sound absorption damping.

Due to the extremely low pressure drop of less than 15 Pa on the air-discharge side and <30 Pa total at full fan level, the Kellner-acoustic housing is the only soundproof enclosure with a demonstrably lower pressure loss (measurement by TÜV Austria) as the fan pressure of the air conditioners according to data sheet of the air-conditioner manufacturers and thus the housing on the market with the lowest power and efficiency loss at full sound insulation performance.

Function principle

The base principle of all housing

models is the retention of the

identical air flow direction as the

built-in outdoor units

models is the retention of the

identical air flow direction as the

built-in outdoor units

To achieve a flawless and efficient function of the built-in outdoor units, the fans must reach the same amount of air as a free blow-out. This is achieved by extremely large-scale and special shaped louvres - so-called „lamella-packs“ - in a special design for hardly measurable, minimal pressure loss. The air flow through the housing corresponds exactly to that of the installed outdoor units - without deflections and without baffles.

Universally applicable

The already factory-assembled housings are divided into different product series (KV, KH, KG) according to the basic function and allow through the many housing series (S, M, X, Y, T, ..) an optimal adaptation to a variety of outdoor units and systems of all manufacturers with very compact external dimensions and small footprint. For installation through doors, the housings can also be very easily disassembled and reassembled on the construction site.

Meets the standards for statics and wind loads

The very stably constructed, self-supporting housing complies with the standards EN1991-1-4 and all static requirements, which are placed on supporting structures. Thus, the plant manufacturer and operator are given full plant safety and protection even with the highest wind loads and exposed locations. Due to the compact design and weighting of the built-on outdoor units on the base frame, a complex substructure and an expensive, deep foundation, e.g. in terms of static mandatory for soundabsorbing barriers, are not required.

„no view, no noise“

The enclosed housing construction providesincreased protection of the built-in devices against wind, hail and snow as well as against vandalism and prying eyes from concerned residents and neighbours. In addition, the front doors can be equipped with an integrated door lock for profile cylinders.